Description

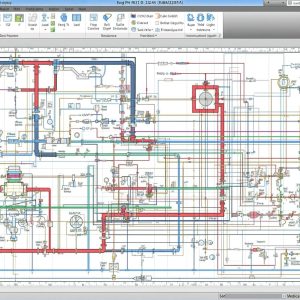

The 3D Refinery Layout Simulation Software enables engineers and project managers to visualize, plan, and optimize refinery layouts in a virtual environment. The software allows detailed modeling of processing units, pipelines, storage tanks, and auxiliary facilities, providing a comprehensive view of spatial arrangements and workflow efficiency. Users can simulate material flow, identify potential bottlenecks, and optimize equipment placement to improve operational performance and safety. Integrated analytics support cost estimation, resource allocation, and scenario-based planning. This software is ideal for process engineers, project planners, and operations teams seeking to enhance refinery design accuracy, reduce design errors, and streamline project execution.

Bilikisu –

Before implementing the $3D Refinery Layout Simulation Software, visualizing optimal equipment placement was a constant challenge, but now, “the ability to virtually walk through proposed refinery layouts and identify potential bottlenecks *before* construction even begins has been transformative; the software’s fluid dynamics simulation feature allowed us to optimize material flow and significantly reduce the risk of pipeline congestion, saving us valuable time and resources, and the collision detection tools were instrumental in preventing costly design flaws and ensuring a safer working environment by proactively addressing potential hazards, ultimately streamlining our entire planning process from conception to implementation thanks to its intuitive interface and powerful analytical capabilities,” resulting in a smoother and more efficient project lifecycle overall.

Chizoba –

As a seasoned refinery design engineer, I was initially skeptical about transitioning to a fully virtual layout simulation, but I have to admit, the results have been truly impressive; “The $3D Refinery Layout Simulation Software completely revolutionized our design process by allowing us to virtually walk through proposed layouts, identify potential bottlenecks, and optimize equipment placement for maximum efficiency, all before breaking ground, the collision detection feature alone saved us countless hours of rework by highlighting potential interference issues between piping and structural elements, and the integrated material flow analysis tools gave us unprecedented insights into the impact of layout decisions on operational costs, this software empowered our team to create safer, more efficient, and ultimately, more profitable refinery designs that would have been impossible to achieve with traditional methods, the ability to simulate various scenarios and quickly compare performance metrics was invaluable in making informed decisions and avoiding costly mistakes, the visualization capabilities were particularly noteworthy as they enabled stakeholders to easily grasp the design concepts and provide valuable feedback, even those without technical expertise, the software became an indispensable tool in our design workflow and significantly improved our project outcomes.” It’s been a genuinely positive experience.

Ademola –

Having struggled with traditional 2D layouts for years, the introduction of true 3D visualization has fundamentally shifted my approach to refinery design, and I can confidently say that “the $3D Refinery Layout Simulation Software has become an indispensable tool for our engineering team, allowing us to proactively identify and resolve potential spatial conflicts and workflow bottlenecks before construction even begins; the ability to dynamically simulate material flow through the proposed layout provides invaluable insights into optimizing equipment placement and minimizing unnecessary movement, which has translated into a noticeable improvement in our predicted operational efficiency; furthermore, the integrated safety analysis features allowed us to identify and mitigate potential hazards early in the design phase, ensuring a safer and more compliant facility; the software’s intuitive interface and robust simulation capabilities have truly empowered us to make more informed decisions and ultimately deliver better refinery designs.” This transformative software has demonstrably streamlined our design process and elevated the overall quality of our refinery projects.

Oluwatosin –

Using this $3D Refinery Layout Simulation Software has been a surprisingly effective tool, and I’m pleased to share my experience; “The software proved invaluable in visualizing potential bottlenecks and optimizing our equipment placement long before we committed to physical construction. Its intuitive interface made it easy to experiment with different layouts and material flow scenarios, allowing us to significantly improve our operational efficiency. The clash detection feature alone saved us countless hours and potential rework costs, and the ability to simulate emergency evacuation routes provided a vital layer of safety planning. Being able to present these simulations to stakeholders with interactive 3D models greatly improved understanding and buy-in, ultimately leading to a more streamlined and safer refinery design.” As a result, our project is now proceeding with greater confidence and a more optimized blueprint.

Habu –

As a refinery design consultant, I’ve tested countless layout tools, but none have streamlined the process quite like this; “The $3D Refinery Layout Simulation Software has drastically improved my efficiency in optimizing refinery designs, allowing me to quickly visualize and test different layouts before committing to costly physical prototypes; the drag-and-drop interface is intuitive, the simulation engine accurately predicts material flow and potential bottlenecks, and the ability to generate detailed reports on space utilization and safety compliance is invaluable for presenting proposals to clients, ultimately leading to better, safer, and more cost-effective refinery designs.”; This software has truly become an indispensable part of my workflow.