Description

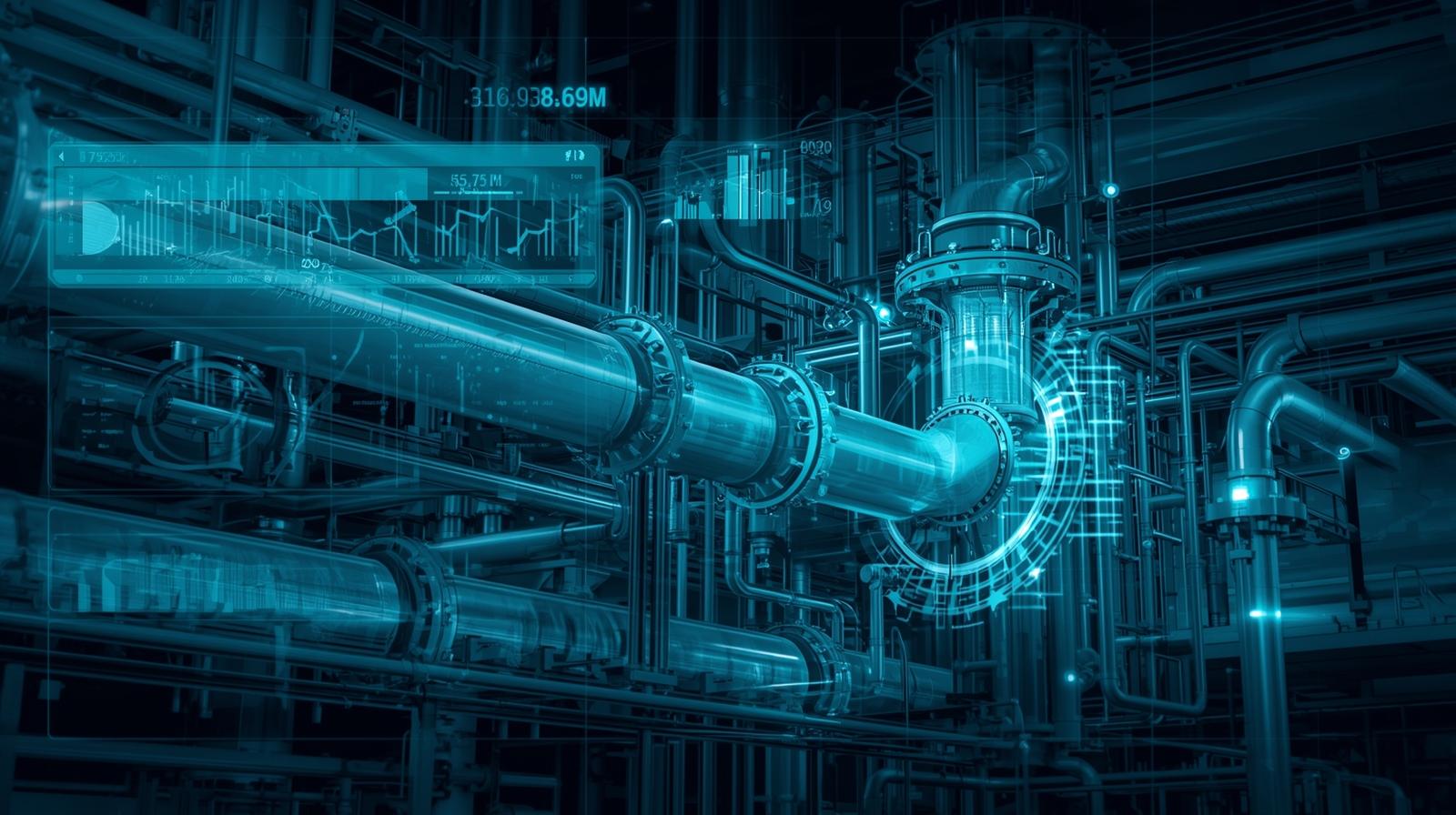

The Predictive Maintenance Software leverages sensor data, historical maintenance records, and machine learning algorithms to forecast equipment failures in refineries. The platform identifies early warning signs, recommends maintenance actions, and prioritizes critical assets to prevent downtime. Users can schedule proactive interventions, optimize spare parts inventory, and reduce maintenance costs. Designed for maintenance engineers, operations managers, and reliability teams, this software enhances equipment lifespan, improves operational safety, and ensures uninterrupted refinery operations.

Ahmed –

As a maintenance engineer constantly battling unscheduled downtime, I was initially skeptical, but now I can confidently say, “The Predictive Maintenance Software for Refinery Equipment has truly revolutionized how we manage our asset health. We’ve seen a significant drop in emergency repairs thanks to its accurate forecasting of potential failures, allowing us to schedule proactive maintenance during planned outages. The anomaly detection feature is particularly valuable, pinpointing subtle deviations in equipment performance that would otherwise go unnoticed until they escalated into major problems. The customizable dashboards provide clear, actionable insights, making it easy to prioritize maintenance tasks based on risk and potential impact. Moreover, the integration with our existing CMMS system was surprisingly seamless, streamlining our workflow and reducing manual data entry. Ultimately, this software has empowered us to optimize our maintenance strategy, leading to increased operational reliability and cost savings by minimizing unexpected shutdowns.” This has allowed us to shift from reactive to proactive maintenance strategies.

Abbas –

As a maintenance manager in a large refinery, I was initially skeptical about predictive maintenance software, but the results I’ve seen from $Predictive Maintenance Software for Refinery Equipment have completely changed my perspective; “The software’s ability to accurately forecast potential equipment failures several weeks in advance has been invaluable. We’ve significantly reduced unscheduled downtime by proactively addressing issues identified by the system’s algorithms. The detailed risk assessments for each piece of equipment, combined with the clear visual dashboards showing potential failure timelines, allow us to prioritize maintenance tasks effectively. The system integrates seamlessly with our existing CMMS, making it easy to schedule work orders and track repairs. We’ve also noticed a considerable improvement in equipment reliability and a reduction in overall maintenance costs since implementing the software.” It’s a powerful tool that’s become an essential part of our maintenance strategy.

Shehu –

Before deploying $Predictive Maintenance Software for Refinery Equipment, we faced constant fire-fighting and unplanned shutdowns. “The ability of the software to accurately predict potential equipment failures well in advance has been nothing short of transformative for our maintenance scheduling; we’re now able to proactively address issues before they escalate, significantly reducing downtime and preventing costly emergency repairs. The user interface is surprisingly intuitive, making it easy for our maintenance team to interpret the predictive data and translate it into actionable tasks. We especially appreciate the customizable alert system that allows us to prioritize critical equipment and receive timely notifications of impending failures. Moreover, the integrated reporting features provide valuable insights into equipment performance trends, enabling us to optimize maintenance strategies and extend the lifespan of our refinery assets.” Consequently, our operational reliability has demonstrably improved, leading to significant cost savings.

Hamsatu –

Before implementing, our refinery maintenance was largely reactive, leading to unexpected shutdowns and budget overruns; however, since adopting, I can confidently say that the “$Predictive Maintenance Software for Refinery Equipment has fundamentally improved our operational efficiency. We’ve seen a significant decrease in unplanned outages thanks to its accurate forecasting capabilities, allowing us to schedule maintenance during planned downtime rather than reacting to critical failures. The real-time data visualizations of equipment health are incredibly intuitive, letting our technicians quickly identify potential issues and prioritize their workload. Furthermore, the software’s ability to integrate seamlessly with our existing CMMS system has streamlined our workflow, and the machine learning algorithms are constantly improving the accuracy of predictions as more data is ingested. The ROI we’ve experienced in just a few months is remarkable, primarily because we now have the data needed to make informed decisions about equipment maintenance, thereby saving both time and resources.” After using this, our team feels far more in control of our maintenance schedule.