Description

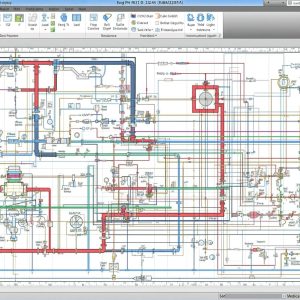

The Storage Facility 3D Modeling Tool enables engineers and designers to create realistic 3D models of storage infrastructure, including tanks, pipelines, and auxiliary systems. The platform supports design visualization, clash detection, and workflow simulation, reducing design conflicts and construction errors. Users can simulate operational scenarios, assess maintenance accessibility, and optimize storage capacity. This tool is suitable for structural engineers, project planners, and facility managers who require accurate modeling to improve design quality, safety, and efficiency in refinery and storage projects.

Ai –

Before using $Storage Facility 3D Modeling Tool, I struggled with visualizing complex pipeline networks and potential tank placement issues, but that’s all changed; “The $Storage Facility 3D Modeling Tool has completely streamlined our design and operational planning process, offering unparalleled visualization of our storage facilities, tanks, and interconnected pipelines, and the clash detection feature alone has saved us countless hours of rework by identifying potential interference issues early on; the ability to simulate workflows within the 3D environment is particularly valuable for optimizing maintenance procedures and training new personnel.” The level of detail and intuitive interface have allowed my team to make more informed decisions, leading to more efficient project execution.

Laraba –

This tool has completely revolutionized our storage facility planning process, and the standout feature has been its intuitive interface. “The $Storage Facility 3D Modeling Tool has proven invaluable for our project teams, enabling us to visualize complex layouts of tanks and pipelines with exceptional clarity. The clash detection functionality alone has saved us countless hours and prevented potentially costly errors during design. Furthermore, the ability to simulate workflows within the 3D model provides a level of operational planning we simply couldn’t achieve before, allowing us to optimize material flow and improve safety protocols. We are now able to present stakeholders with a much clearer understanding of our project designs, leading to faster approvals and smoother execution, and the integration with our existing procurement system has streamlined our ordering process.” The seamless integration with our existing platform and the level of detail it provides make it an essential tool for anyone involved in storage facility design and operation.

Ladi –

I was initially skeptical about using a virtual modeling tool for our storage facility planning, but the experience with $Storage Facility 3D Modeling Tool completely changed my perspective; “The clarity and precision of the 3D models are outstanding, allowing us to visualize complex pipeline layouts and tank configurations with unprecedented ease. The clash detection feature has already saved us significant time and resources by identifying potential problems before construction even begins, and the ability to simulate workflows within the model gives us a powerful tool for optimizing operational efficiency. It has streamlined our design process significantly, improving communication between teams and ultimately leading to more informed decisions regarding resource allocation and logistical planning.” We’re now looking at expanding its use across our other sites.

Bukola –

I was initially skeptical about integrating 3D modeling into our workflow, but the results speak for themselves; “The $Storage Facility 3D Modeling Tool has completely transformed the way we approach storage facility design and operational planning. The visualization capabilities are exceptional, allowing us to gain a far deeper understanding of the spatial relationships between tanks, pipelines, and other critical infrastructure. The built-in clash detection feature has already saved us from several potentially costly errors during the design phase, and the workflow simulation tools are invaluable for optimizing operational processes before any construction even begins. Being able to virtually walk through the facility and identify potential bottlenecks or safety concerns has significantly improved our planning accuracy and reduced project timelines. This tool truly empowers informed decision-making and promotes proactive risk mitigation.” Consequently, our project timelines have become more predictable and the overall efficiency of our design process has seen a marked improvement.

Celestine –

Using $Storage Facility 3D Modeling Tool has been a surprisingly effective addition to my workflow, and I’m happy to share my experience. “The ability to accurately visualize our tank farms and pipeline networks in 3D before any physical construction begins has already saved us significant time and money; the integrated clash detection is incredibly precise, preventing costly errors during the design phase that we previously wouldn’t have caught until much later. Workflow simulation, especially, has been invaluable for optimizing maintenance schedules and minimizing downtime during planned outages; being able to see potential bottlenecks and safety concerns in a virtual environment allows us to proactively address them, leading to far more efficient and safer operations overall, something that’s crucial in our industry.” I’ve found this tool particularly beneficial for communicating complex layouts and scenarios to both internal teams and external stakeholders, improving clarity and facilitating better collaboration.