Description

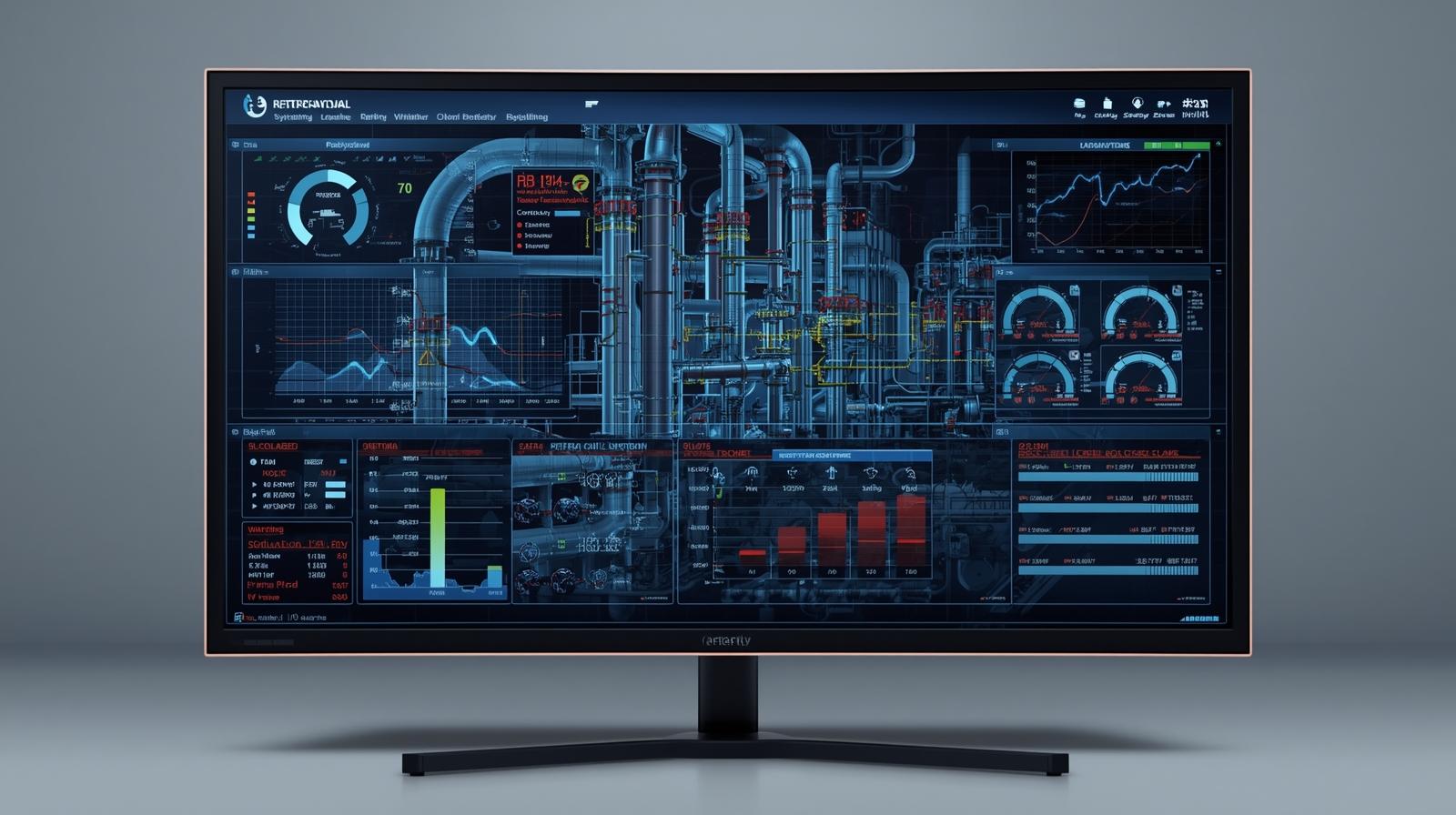

The Refinery Process Control Simulation Software allows engineers and operators to model and simulate process control systems in refineries. Users can test control strategies, optimize operational parameters, and monitor process responses in a risk-free digital environment. The software supports training in advanced control loops, alarm handling, and operational optimization. It is suitable for control engineers, process operators, and trainers aiming to improve system understanding, operational efficiency, and safety. Scenario simulations allow users to predict outcomes and mitigate potential operational risks.

Tanko –

The implementation of this software has significantly improved our team’s preparedness for complex refinery scenarios; “The $Refinery Process Control Simulation Software has proven to be an invaluable tool for our team. The ability to realistically simulate various process control scenarios, from routine adjustments to emergency shutdowns, in a safe, virtual environment is unparalleled. We’ve particularly benefited from the software’s comprehensive library of control system models and the intuitive interface that allows even novice users to quickly grasp key concepts. The level of detail in the simulation, including realistic equipment behavior and dynamic responses to changing parameters, has allowed us to fine-tune our control strategies and identify potential operational bottlenecks before they occur in the actual plant. Furthermore, the training module has accelerated the onboarding process for new engineers, ensuring they are equipped with the practical skills necessary to confidently manage the refinery’s control systems. This has led to a demonstrable improvement in operational efficiency and a reduction in costly errors.” ultimately leading to a more proficient and confident team.

Ann –

Before implementing any major process changes in our actual refinery, using this tool has proven invaluable; “The $Refinery Process Control Simulation Software provided an incredibly realistic environment to test new control strategies without risking downtime or impacting production. We were particularly impressed with the software’s ability to accurately model complex interactions within the distillation column and catalytic cracking units, allowing us to fine-tune parameters and identify potential bottlenecks before they ever occurred in the real world. The training modules for our new engineers were also significantly more effective thanks to the hands-on experience they gained in the simulation environment, allowing them to quickly grasp the nuances of process control and build confidence in their abilities. This has translated into smoother startups, reduced operational variability, and ultimately, a more efficient refining process overall.” That kind of predictive power is exactly what we needed.

Fatimat –

Before implementing new control strategies in our live refinery, we rely heavily on simulations, and this software has become an indispensable tool in that workflow. “The $Refinery Process Control Simulation Software provides an incredibly realistic and responsive virtual environment for testing and refining our control logic. The ability to model complex interactions and predict system behavior under various operating conditions has significantly reduced the risk of unforeseen issues during real-world implementation. Specifically, the intuitive interface for building and modifying process models, combined with the comprehensive library of pre-built components, allows us to quickly prototype and evaluate different control approaches. Furthermore, the detailed performance metrics and visualization tools provide invaluable insights for optimizing control parameters and maximizing efficiency, resulting in smoother operations and improved overall performance.” Consequently, we’ve seen a marked improvement in the success rate of our control system upgrades.