Description

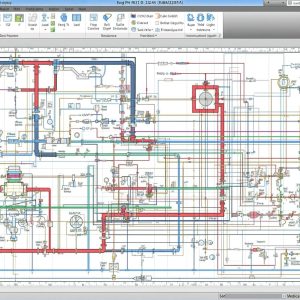

The Tank Farm Layout Planning Software provides engineers with tools to design and optimize storage tank facilities efficiently. Users can plan tank placement, access roads, piping connections, and safety buffers while simulating operational workflows. The software evaluates spatial constraints, risk zones, and maintenance access to ensure regulatory compliance and operational safety. Integrated analytics allow cost estimation, scenario testing, and optimization of tank farm layouts. This software is ideal for storage facility planners, process engineers, and project managers aiming to enhance safety, efficiency, and resource utilization.

Olanrewaju –

Before using $Tank Farm Layout Planning Software, I dreaded any new tank farm project; the spatial puzzle felt impossible to solve efficiently. “Using this software was a revelation; it significantly streamlined our layout planning process. The 3D visualization is incredibly helpful for spotting potential clashes early on, saving us valuable time and money in rework. What really stood out was the software’s ability to automatically evaluate different spatial arrangements based on safety regulations and operational workflows, quickly identifying the most efficient and compliant options. The built-in tools for calculating storage capacity and optimizing piping routes were also a huge plus, ensuring we maximized our space while maintaining safe and efficient operations.” The reduced planning time alone makes it an indispensable tool.

Adama –

Before utilizing $Tank Farm Layout Planning Software, planning out new tank farms was a headache involving countless spreadsheets and manual iterations. “This software has completely streamlined the process, particularly the visual drag-and-drop interface for arranging tanks and piping. The built-in safety analysis tools are also invaluable, allowing us to proactively identify and mitigate potential hazards before construction even begins. Furthermore, the software’s ability to optimize layouts for efficient workflows and minimize space requirements has led to significant cost savings on our projects, and the automated report generation is a huge time-saver when presenting proposals to clients. We’ve found it to be an essential tool for any oil and gas professional dealing with tank farm design.” The difference in efficiency and accuracy is remarkable.

Comfort –

My team was initially overwhelmed with the sheer complexity of redesigning our tank farm layout, but everything changed once we implemented the $Tank Farm Layout Planning Software; “The software’s intuitive interface and powerful visualization tools allowed us to explore numerous layout options quickly, optimizing for both spatial efficiency and safety protocols. The built-in compliance checks were invaluable in identifying and mitigating potential hazards before committing to a final design, significantly reducing the risk of costly errors and delays during construction. We particularly appreciated the ability to simulate operational workflows within different layouts, enabling us to fine-tune the design for optimal efficiency and minimize operator movement. The comprehensive reporting features also provided a clear and concise summary of key performance indicators, facilitating informed decision-making at every stage of the project.” Now, we feel confident in our tank farm design and its long-term operational viability thanks to this tool.

Gloria –

Having struggled for years with manual tank farm layout planning and its inherent limitations, I can confidently say this software has been a welcome change; “The $Tank Farm Layout Planning Software has truly streamlined our design process, allowing us to rapidly iterate on different configurations and immediately see the impact on safety clearances and operational efficiency. The intuitive interface made it easy to import our existing site data, and the built-in algorithms for optimizing spatial arrangement have saved us a significant amount of time and resources in identifying potential bottlenecks and safety hazards before construction even begins. Being able to visually simulate operational workflows within the designed layout has proven invaluable in ensuring smooth tank truck access and minimizing turnaround times, making this a key component of our planning process”. It’s a tool that empowers our team to make data-driven decisions and significantly improves our overall planning outcomes.